You don’t want to get anywhere close to a rotating cutter in a NC machine center.įortunately, that was 20 years ago.

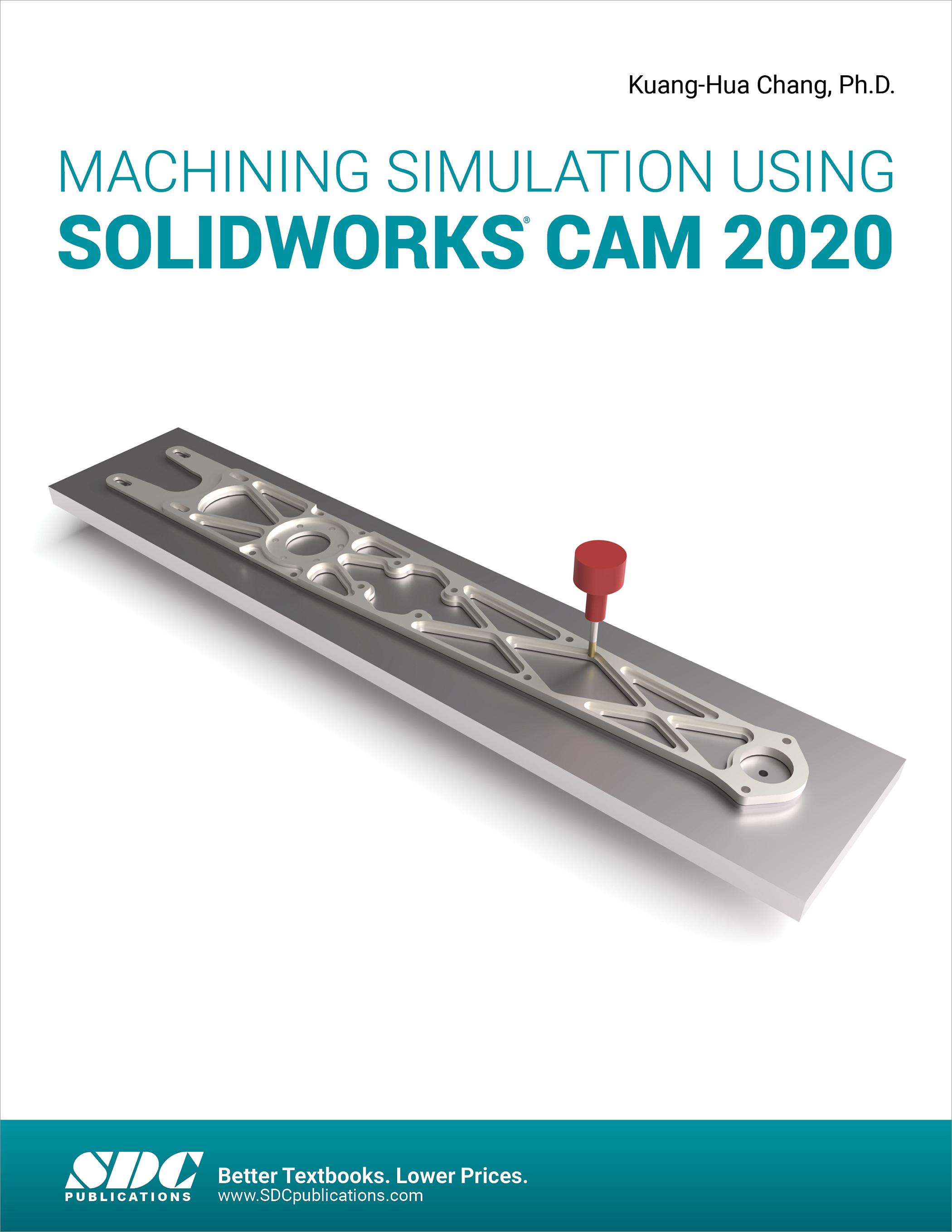

Of course, here I mean “hold its hand” metaphorically, not literally. You have to hold its hand and tell it to move from the X, Y, Z location of (0,0,0) to (1,0,0) and then to (1,1,0) and finally to (1,1,1), rather than directly from (0,0,0) to (1,1,1). Please remember that all the operations are sequential. Then I have to recalculate manually, add necessary operations and rewrite many lines of the code to accommodate the changes. The designer decides that one hole needs to be smaller or a face needs a finer surface finish. Let’s say that I finally manage to finish all the lines perfectly. Why didn’t the cutter move? Why didn’t it rotate? Why did it move so slowly? Why were the cutter and the part so far apart? These were the typical puzzles I had to figure out, if the cutter hadn’t destroyed the machine itself by cutting into the workbench yet. Of course, my code was full of miscalculations and I had to debug it on the fly with a simple milling machine. Literally, I had to write the texts line by line, such as “Select this milling cutter, move in X direction by 0.5 mm and in Y direction by 0.25 mm or retreat rapidly to the origin…” A simple machining operation such as drilling several holes can easily lead to hundreds of lines of texts. However, 20 years ago, I had to calculate the cutter moves and write the code manually. I hope that you never have to deal with this type of code manually. A snapshot of the NC code for a milling machine. As you may have guessed, the busy texts are the Numeric Control (NC) code to drive machining.įigure1. Would you recognize the texts in Figure 1? You don’t have to.

0 kommentar(er)

0 kommentar(er)